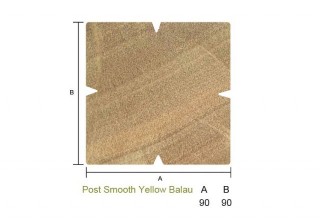

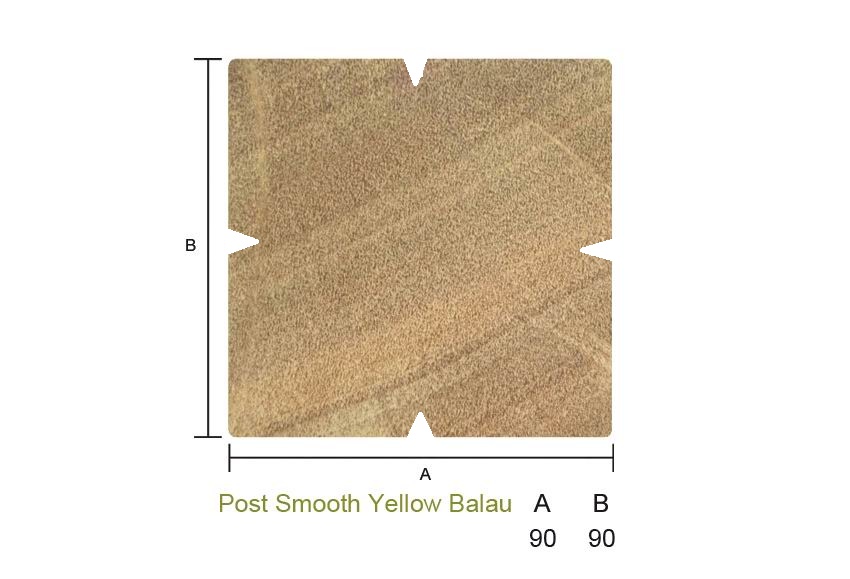

Please note the Smooth Post now has one small v groove on each face this is due to exporting rules from country of origin

Please find below our description of this specie in an attempt to give as much detail of this timber to help both the trade person and ley person make an informed choice. We believe our stocks are among the best available in the UK.

We recommend customers order +10% over and above requirements to allow for waste on your project. We cannot supply every length defect free.

Certification

SLVK certified. The SVLK assurance scheme is a mandatory system that requires all timber from state-owned and private forests in Indonesia to obtain verification of legality – as a guarantee that the timber originates from legal, sustainably-managed sources.

Grading

Unlike other species, Yellow Balau has no specific ‘grading rule book’ and generally is sourced on the trust basis that certain mills produce a superior production selecting out lower grade boards for other uses. We use our considerable experience to source from the best shippers and to the specification that we believe is the best in the UK.

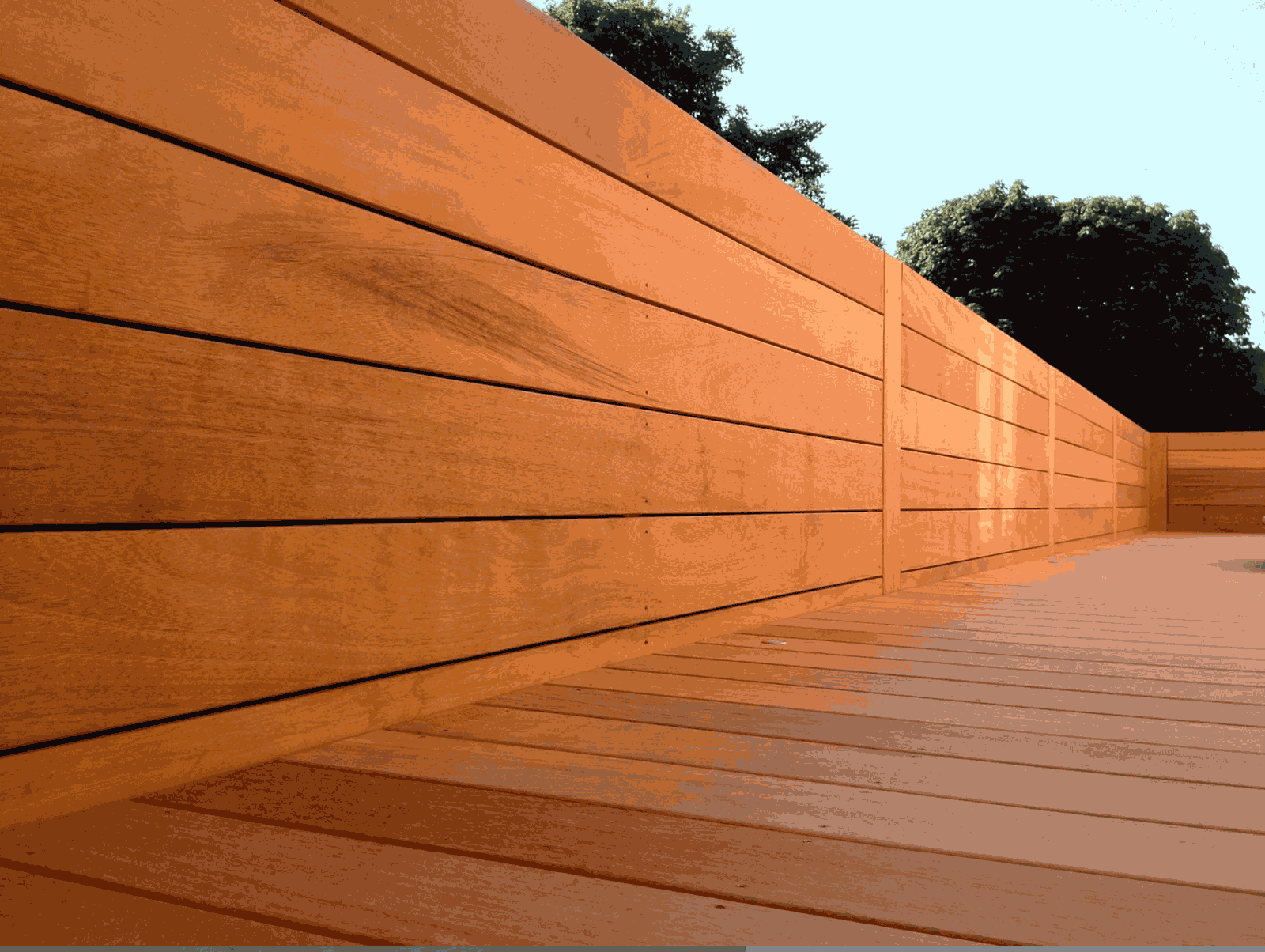

Appearance

Generally a Golden brown colour with occasional lighter and darker colour boards. Boards are hardwearing and dense. Boards are packed with ‘cross stickers’ to aid in drying and make the bundles safe to handle these can sometimes leave marks across the boards which are not regarded as a defect. Boards are generally supplied to full lengths or a fraction over the length with waxed ends to assist in reduction in end splitting. Occasional boards will have slight areas of missed machining and possible the odd ‘pin worm’ holes these are again allowed within this specie and should be accounted for in the recommended waste to be factored in.

Lengths

The lengths we have available are listed in the drop-down box to the right and can be selected and ordered online. Boards are generally straight but more likely to be Bent in some of the longer boards. To overcome the odd bent board we recommend the purchase or hire of our ‘hardwood wrench’ when fitting long lengths.

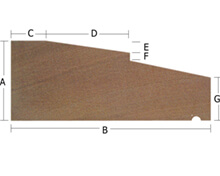

Machine tolerances

Yellow Balau is machined at source in Indonesia and due to the drying & shipping process, the boards can vary in width when they reach their final destination. It is fairly common to find boards within a batch to vary 5% in width from board to board and more rarely up to 7.5% tolerance can be expected.

Moisture Content

Yellow Balau is generally supplied as ‘Air Dried’ (approx. 18%) but in many cases and to speed the drying phase up we source Kiln Dried Stock. This Kiln Drying process is not like the typical sub 10% that is required for timber generally used internally but rather is kiln dried to 10-18%. This is just enough to get rid of the free water without banishing the bound water and hardening the cell walls of the wood and therefore making it more brittle and resistant to change.

Specie

Sourced from Indonesia, Yellow Balau is a very hardwearing durable decking which is classed at the high D50 strength rating. Density is high with an average weight of 980 kilos per m3. Decay resistance is rated as high and longevity is rated as 25 years +.

Fitting

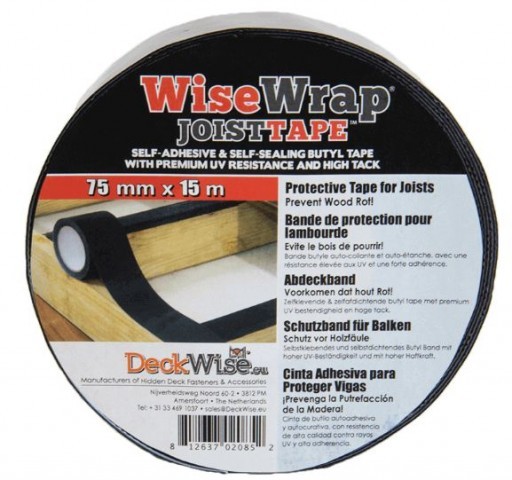

Where possible and depending on the time of year boards should be laid out on the deck frame for a period of time to acclimatise and allow final drying and help reduce shrinkage after installation. The frame should be built with larger section sizes of tanalised Softwood ideally 50x150mm or bigger as the frame will generally rot long before the Yellow Balau decking. We recommend some coats of further weather protection be added to the frame such as black bitumen to provide further longevity. Good drainage under the frame and ideally some airflow is essential to the life of the frame and also the stability of the decking boards on top. Frame centres are recommended at 400mm – 500mm with 450mm being the industry standard. Yellow Balau boards should be trimmed on both ends to square up and remove the wax ends. Yellow Balau Decking Boards should be securely fixed down where they cross every joist either with Spax Stainless Steel decking screws. For further information please see the ‘How to fit Yellow Balau Hardwood Decking’ video on the home page of our website

Please DO NOT fit Yellow Balau decking with any camo-fix-style system or any side-fix system that restricts the board’s ability to expand or contract in any way. We recommend pre-drill and screwing through the face with Spax stainless steel decking screws only.

Finishing for silvered weathered look

Install decking and leave to silver over time no maintenance required.

Finishing maintaining/enhancing colour using Owatrol Trade quality products

1st Option (recommended)

1) Leave for approximately one year to allow natural weathering to breakdown Millglaze*

2) Wet timber scrub off ground in dirt, while still wet apply Net-Trol Wood cleaner & Colour restorer 3) Leave for 10 – 20 minutes (do not allow to dry apply more Net-trol or damp with water mist)

4) Wash off with plenty of water

5) Leave to fully dry usually 24 hours

6) Apply Textrol penetrating oil wet on wet two-coat application

7) Repeat approximately every 18 months or as timber fades this will depend on exposure to sunlight

2nd Option

1) To achieve oiled finish on newly installed decking Millglaze* must be removed first, to do this wet timber and apply diluted Prepdeck (dilute 1predeck:4water for Yellow Balau)

3) Leave Prepdeck to work 10 – 30 minutes do not allow to dry into decking spray mist water if required.

4) Rinse off Prepdeck with plenty of water

5) Neutralise Prepdeck with diluted Net-trol (1:1water) to stop Prepdeck reactivating when it becomes wet

6) Leave to fully dry usually 24 hours

7) Apply Owatrol Deks Olje D1 saturating oil (note this oil has minimal UV protection so will fade)

Note 1 – Always work small manageable areas of the decking of say 2m x 1m rather than trying to tackle the complete deck in one go and risk products like Prepdeck or Net-Trol drying into the decking

Note 2 – If decking has become faded do not just apply more oil, the surface must be prepared first with Net-Trol following steps 2) to 6) on ‘1st Option’

*Millglaze is the compacted surface which occurs during the machining process. The heat from the cutters draws natural oil in the timber to the surface compacting the fibres and creating a hard slightly shiny surface which will prevent an oil finish from penetrating as intended.

Click & Collect

Click & Collect