- TEL : 01277 890 783

- EMAIL : sales@southgatetimber.co.uk

- Collections Monday to Friday 9:00 - 16:00

exc VAT

Account

You currently have no items in your shopping cart.

-

DECKING

- CLADDING

-

Western Red Cedar Cladding PEFC

Thermo Ayous Cladding

Thermory Thermo-Ash Cladding

Douglas Fir Cladding PEFC

Larch Cladding ***FSC®*** & PEFC

Thermowood Pine Cladding PEFC Far Eastern Hardwood Cladding PEFC & SLVK

Thermory Radiata Pine Cladding ***FSC®*** Black Barn Cladding PEFC

Cedar Shingles & Ridge Tiles PEFC Thermory Thermo-Ash Decor Rhomb Tiles Internal

Cedral Cement Board Cladding

-

- FENCING / PAR

- SLEEPERS

-

FIXINGS & TREATMENT

-

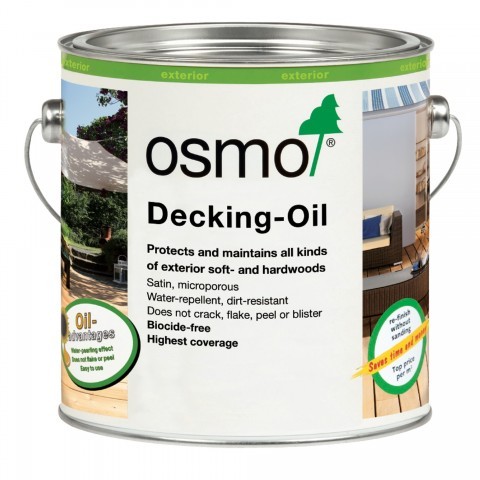

Osmo Treatment & Accessories Owatrol Treatment & Accessories Deckwise Hidden Fixings & Accessories

Thermory Treatment & Fixings Exclusive Bundle Deals Spax Specialist Decking Screws Spax Stainless Steel Facade Screws Spax Construction Screws Decking Accessories

Stainless Steel Nails

Paslode Stainless Steel Brads Walther Strong Deck Tape

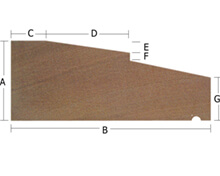

Treatment Samples Brushes & Application Tools Drive Bits Router Bits & Plug Cutters

Cedral Accessories

-

- MOULDINGS

- SAWN

- Special Offers

Click & Collect

Click & Collect